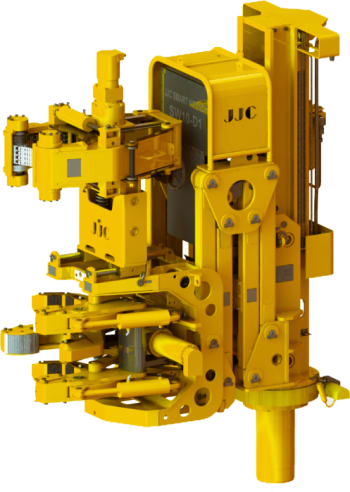

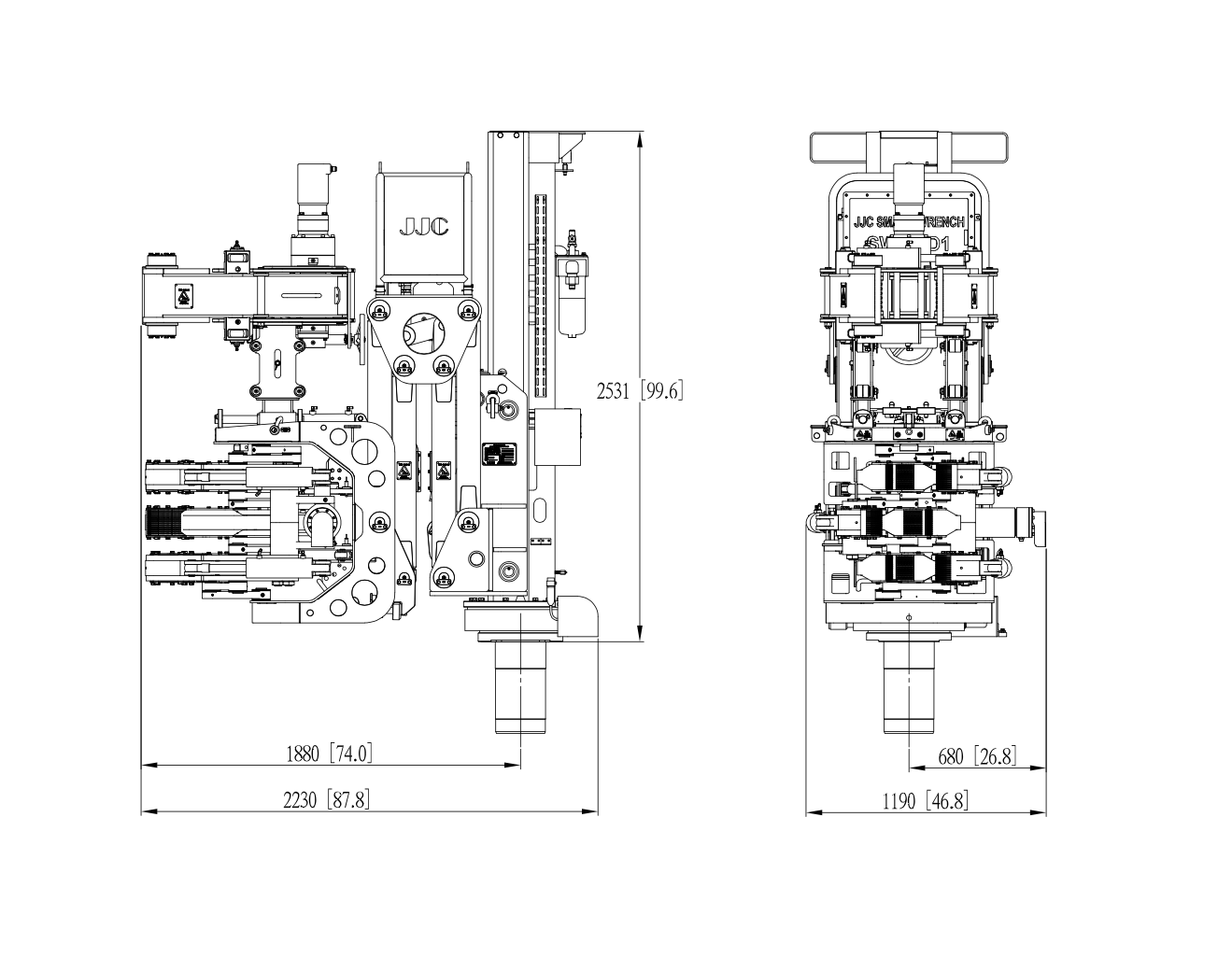

The smart wrench is a drill floor robot used for making up and breaking out the tool joints of oil & gas drilling tubulars. The equipment applies patented chain-based spinning wrench and a patented smart torque wrench, which can carry out the making up and breaking out operation quickly and safely. AI machine vision and low-temperature upgrade packages are optional.